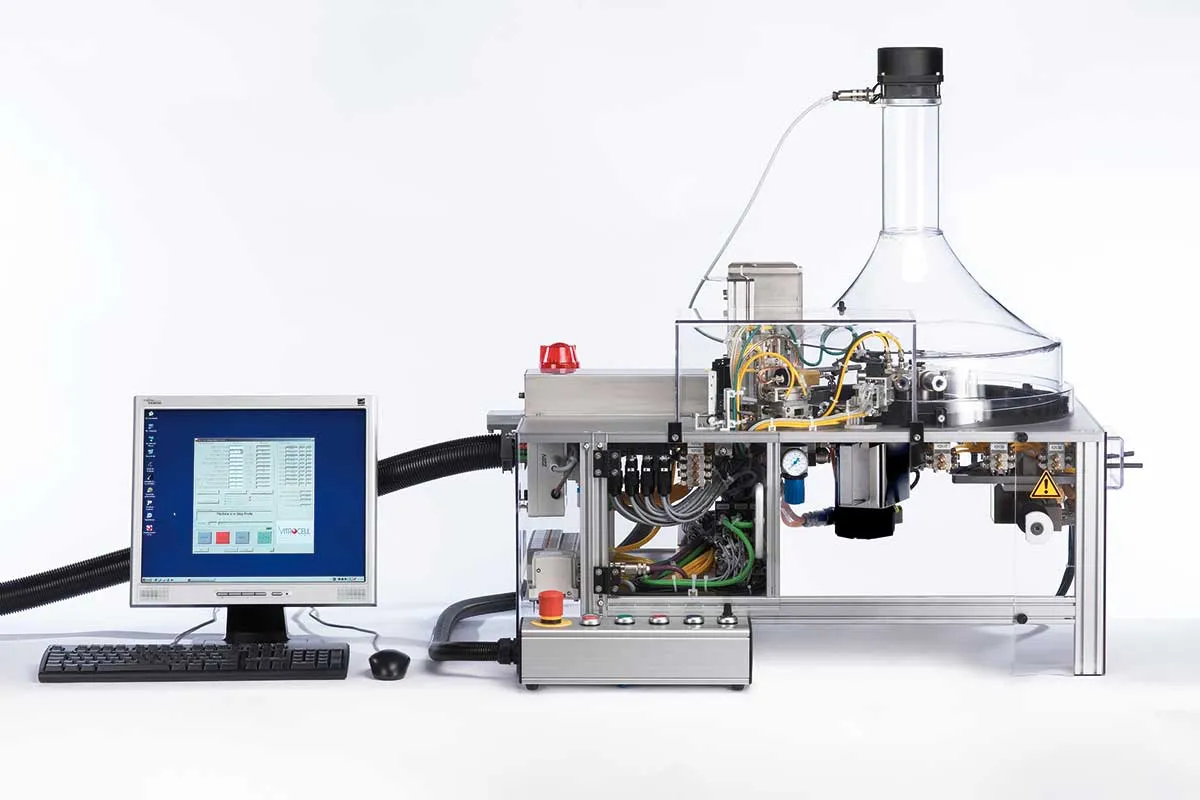

Fully automated smoking robot for conventional and electronic cigarettes.

The smoking machine VC 10® is specially designed to fulfill the requirements of whole smoke and aerosol generation for in vitro experiments. It is suitable for conventional and electronic cigarettes.

The VC 10® offers significant advantages over other commercial smoking machines.

The standard magazine takes up to 20 cigarettes and larger versions are also available. They are suitable for storage in the climatization chamber for pre-conditioning of the cigarettes.

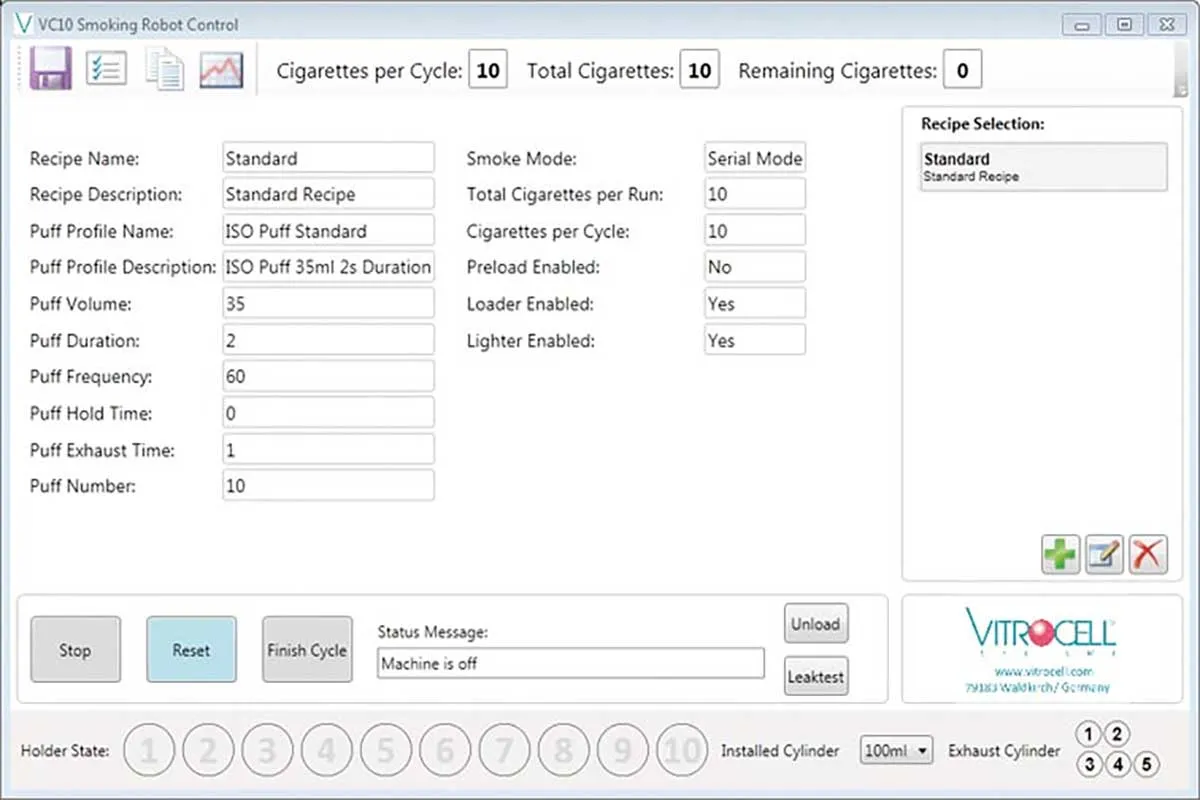

There is the option to activate the leak detector prior to each experiment. The detector confirms the tightness of the system including cigarette holders and pump. The results are logged in the study files.

The loading of the cigarettes into the cigarette holders takes place fully automatically and without damage to the cigarette. The cigarette holders are equipped with labyrinth seals as required by ISO 3308:2012.

Secure and tight connection of any puff-actuated device.

Find more information here

The electric lighter ensures the automatic ignition and a safe procedure without cigarette damage.

The syringe pump is controlled by a linear motor with high precision. The pump can be dismantled for cleaning and refitted again in a few minutes.

The rotation of the port holder is controlled by a stepper motor with highest precision.

The Cambridge filter can be mounted easily into the system for analytical purposes.

The integrated fan evacuates the sidestream smoke. The air flow at the cigarette holders is adjusted by the fan speed.

The IR-sensor can be adjusted to a fraction of a millimeter and transmits reliable signals to the pump and butt extractor. If the critical butt length is reached, the pump stops immediately. Alternatively, it is also possible to work with a defined number of puffs.

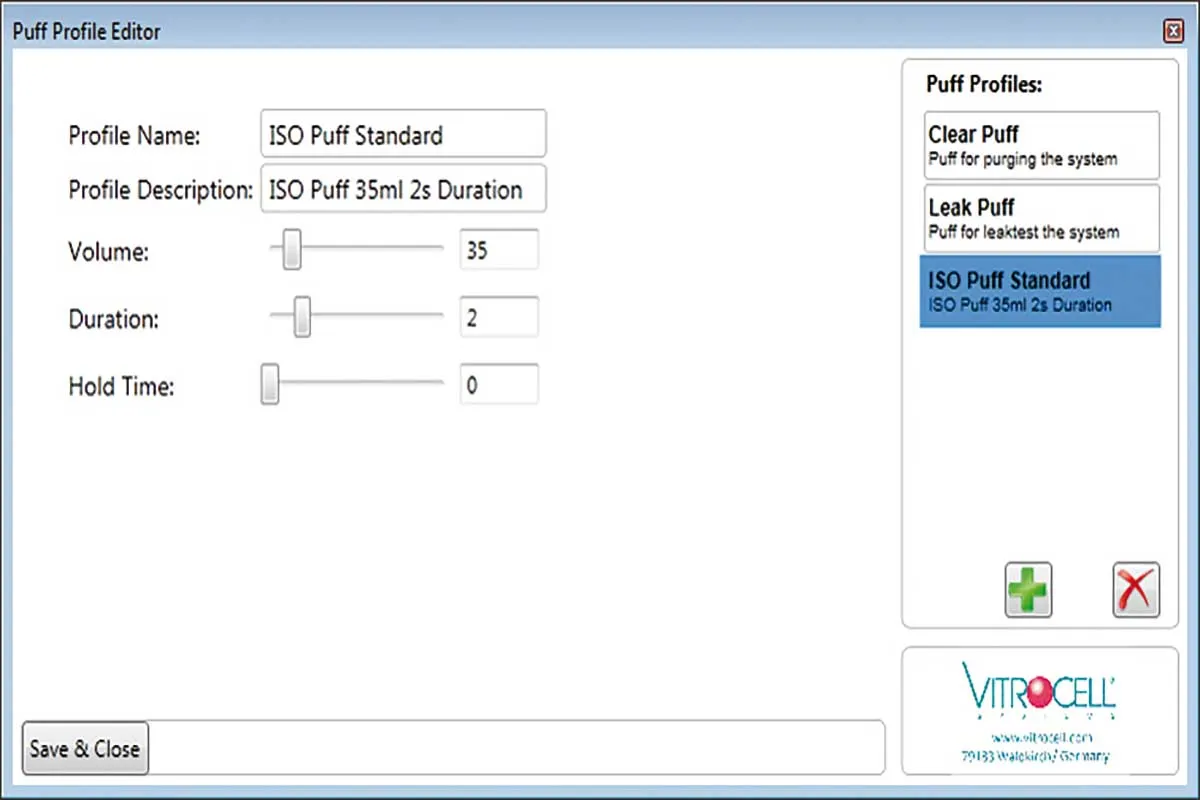

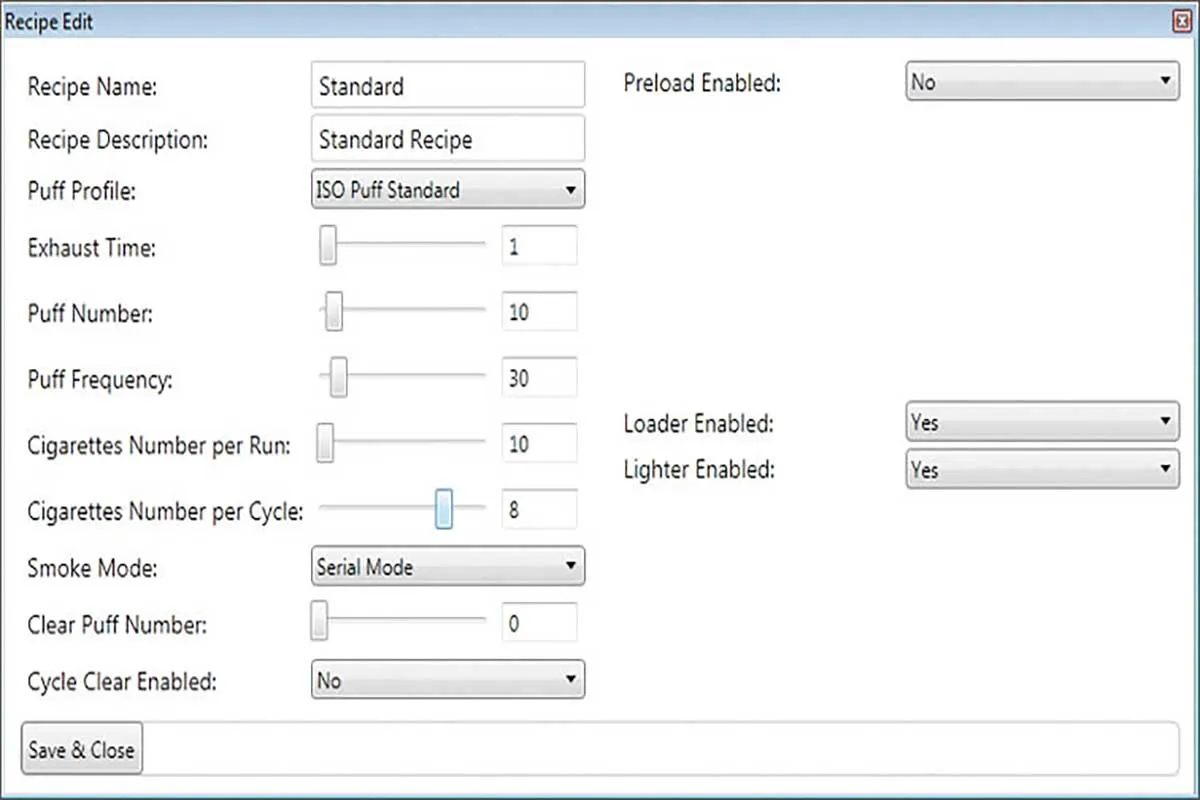

The operation is controlled by Beckhoff software in conjunction with Microsoft Windows 10®. This setup offers extensive possibilities for integration with common Microsoft Office® applications and the exchange of data with Excel®-sheets.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!