When using the Continuous Flow Exposure Systems, cell cultures are exposed to a continuous flow of gases, complex mixtures or particles. Only this exposure principle is suitable for aerosols in which both gas and particle phase are of relevance.

The advantage of this method is the possibility to realize long-term exposures. In the VITROCELL® standard systems exposure durations are normally up to 6 hours, whereas the VITROCELL® Automated Exposure Stations make exposures for 24 hours possible.

Continuous Flow Exposure is used for gases, chemicals or materials which are available in larger quantitities (several g) under a constant delivery. When scarce and very expensive materials need to be tested, this method is less suitable. We recommend in these cases Single Droplet Sedimentation or Dry Powder Systems.

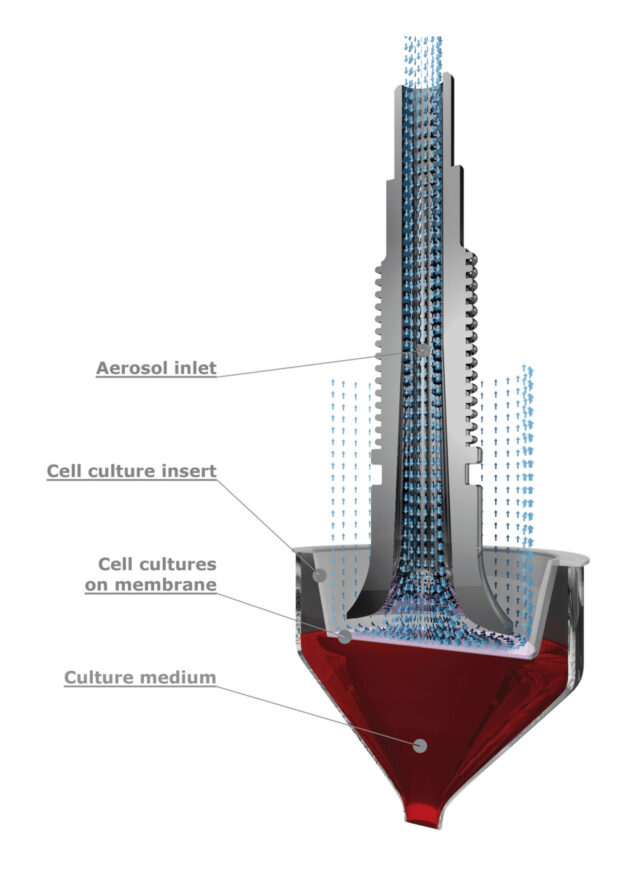

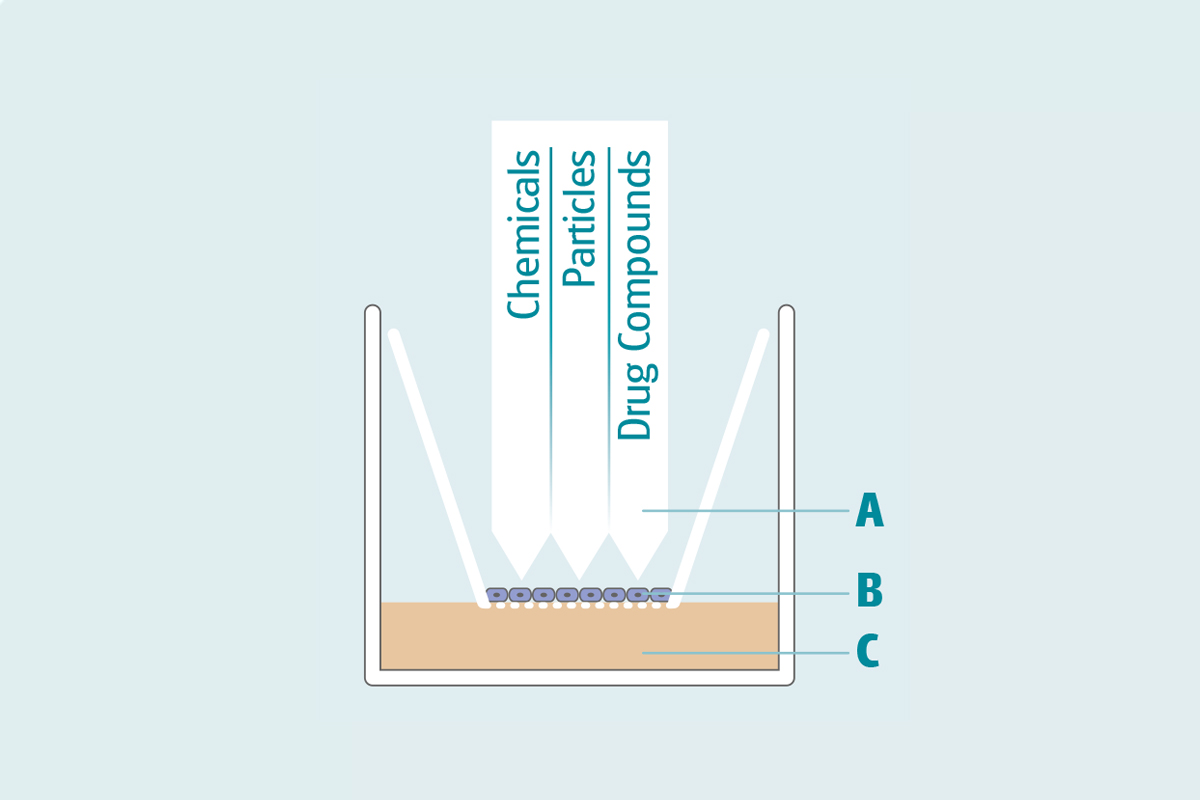

VITROCELL® exposure systems are designed for the direct exposure of mammalian cells or tissue at the Air/Liquid Interface - suitable for exposure of all cell types that can be cultivated on microporous membranes.

This approach is by far closer to the actual human situation than submerged exposure.

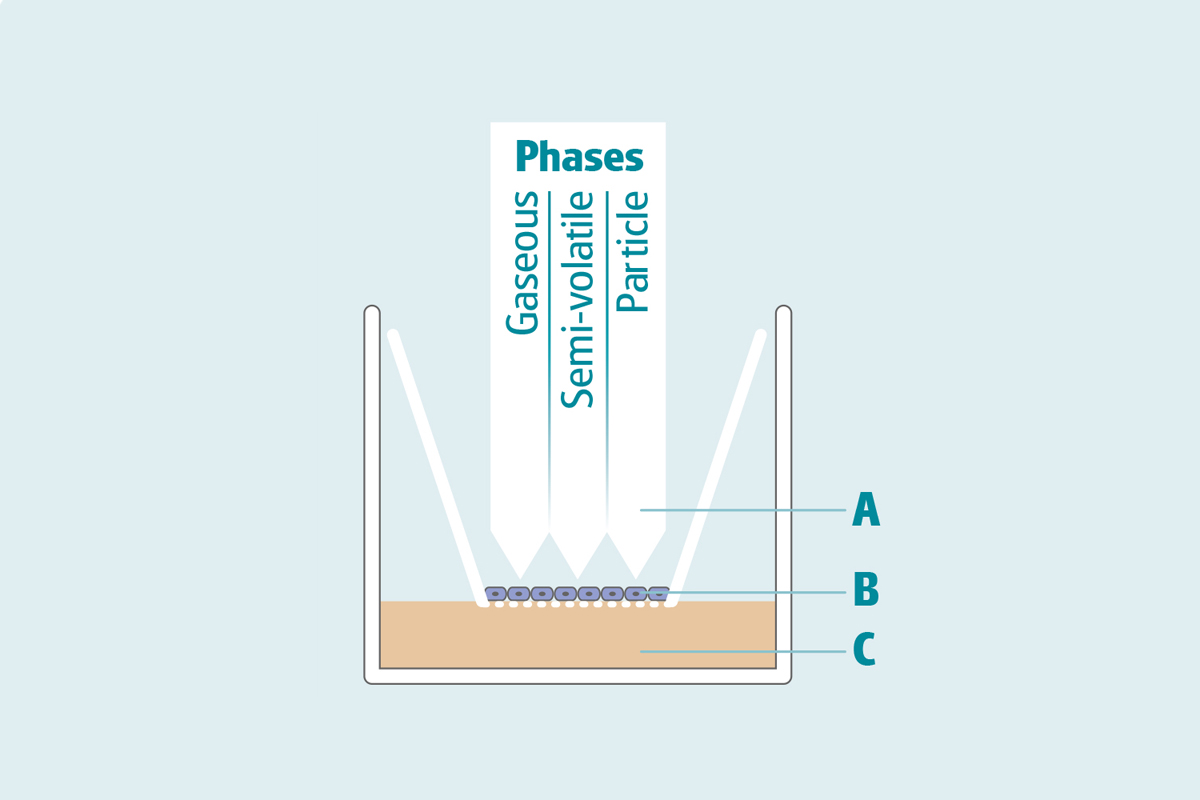

A: Direct and controlled exposure of test atmosphere to cells

B: Cells on membrane

C: Media below cells

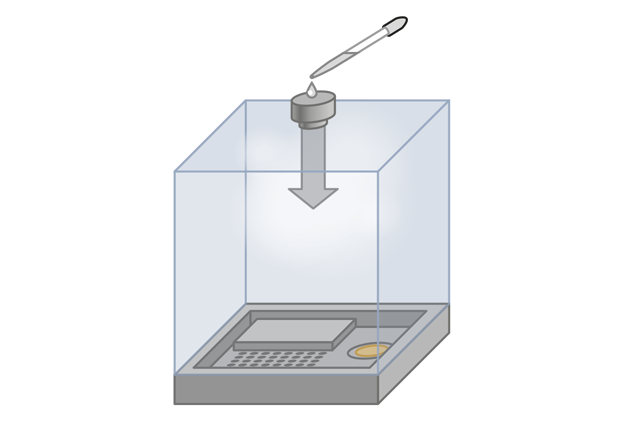

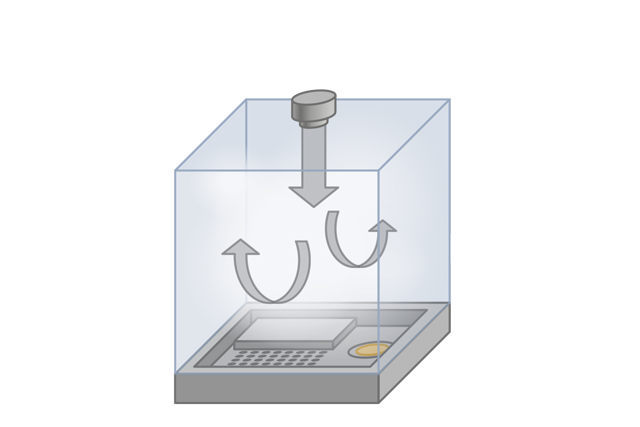

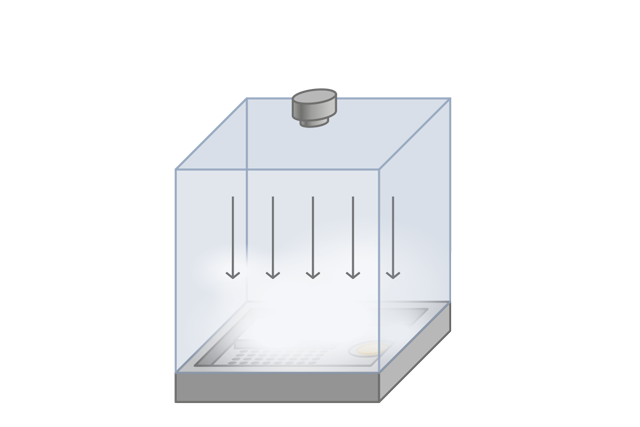

Single Droplet Sedimentation Systems are specifically designed for dose-controlled and spatially uniform deposition of liquid aerosols on cells. Test substances are chemicals or particles brought into suspension with e.g. PBS.

The aerosol is applied for a short time of approx. 3 – 6 minutes.

This method is well suited for scarce and expensive suspensions or materials which can be brought into suspension first, such as new drug candidates or particle samples from the environment.

Nebulization volumes range from 15 – 300 µl. Aerosolization is performed directy into the cell culture exposure chamber. Aerosolization can be repeated several times to obtain a dose-response profile.

Emission of Cloud

Homogeneous Mixing

Gravitational Settling

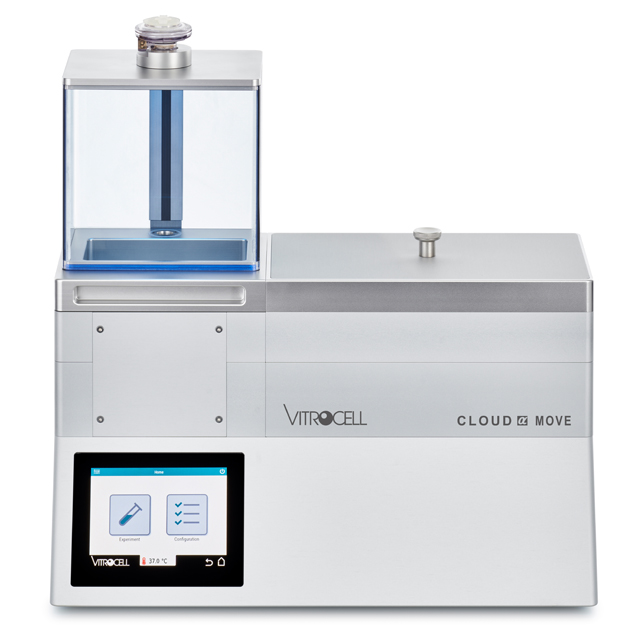

Years of experience and customer feedback led to the development of the new VITROCELL® Cloud Alpha. The design and enhanced functionalities offer an exceptional user experience.

Is designed for lower nebulization volumes and very high depostion efficiency and combines high throughput testing with ease of use.

For automated and repeated row-by-row exposure of 12-, 24- and 96-well sized cell culture inserts. The ideal device to obtain a dose-response relationship in one experiment.

In response to the scientific need to expose in physiologically relevant conditions, the VITROCELL® Cloud Alpha exposure devices have been specifically designed to enable direct exposure of mammalian cells or tissue at the Air/Liquid Interface. Here the cell cultures are not covered with media as opposed to submerged conditions which cause an undesired interaction of the formerly airborne substances with the culture media.

Cell systems cultivated on membrane inserts are exposed at the Air/Liquid Interface (ALI) so that the test substances are received directly. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

A: Direct and controlled exposure of test atmosphere to cells

B: Cells on membrane

C: Media below cells

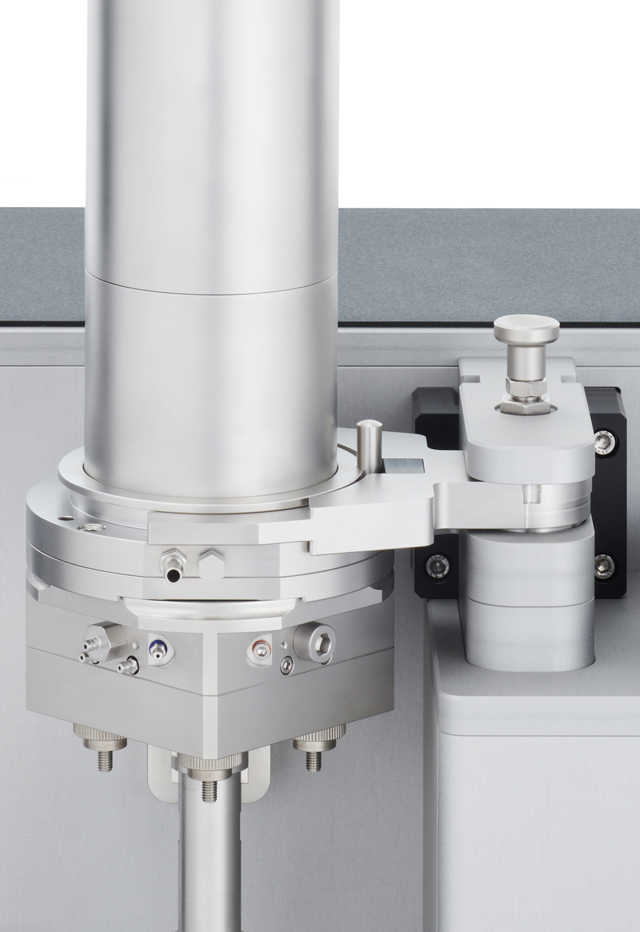

VITROCELL® Dry Powder Exposure Systems are specifically designed for direct aerosolization of smallest quantities of dry powders without the need of transfering them in suspension first. Thus, especially scarce and very expensive materials can be well used with this method, such as new drug candidates or particle samples from the environment.

Here quantities from 1 – 100 mg can be aerosolized. Aerosolization is performed directy into the cell culture exposure chamber. Aerosolization can be repeated a few times to obtain a dose-response profile.

VITROCELL® PowderX is designed for the use of 12- or 24-well sized inserts.

The system features a very intuitive user experience and extremely easy handling.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!