For exposure of cell cultures to liquid aerosols at the Air/Liquid Interface

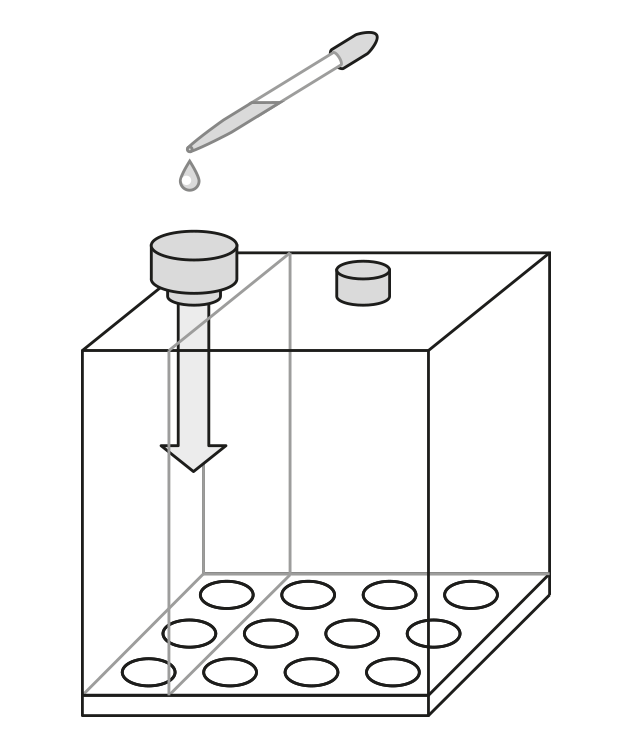

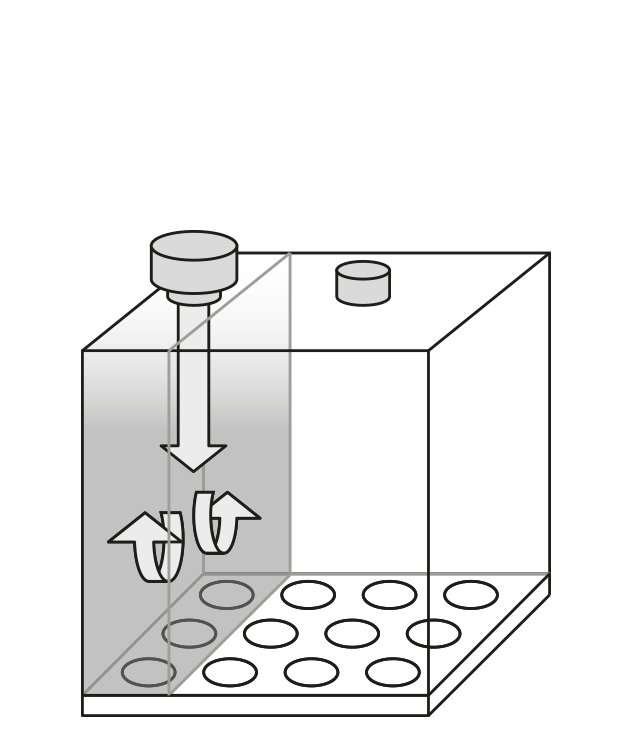

The VITROCELL® Cloud Alpha 12 is our innovation in the Cloud family and presents a great leap forward in automated exposure of cell cultures. It combines high deposition efficiency with ease of use. The development is based on the well-known and frequently published VITROCELL® Cloud formats (12- and 24-well) of the first generation. It’s functionality enables fully automated processes with an all-in-one control unit. Everyday experiments at the Air/Liquid Interface (ALI) have never been easier.

The Cloud Alpha 12 was developed as a result of numerous customer requests and is capable to expose mammalian cell cultures in 12- or 24-well sized cell culture inserts. All commercial brands are supported.

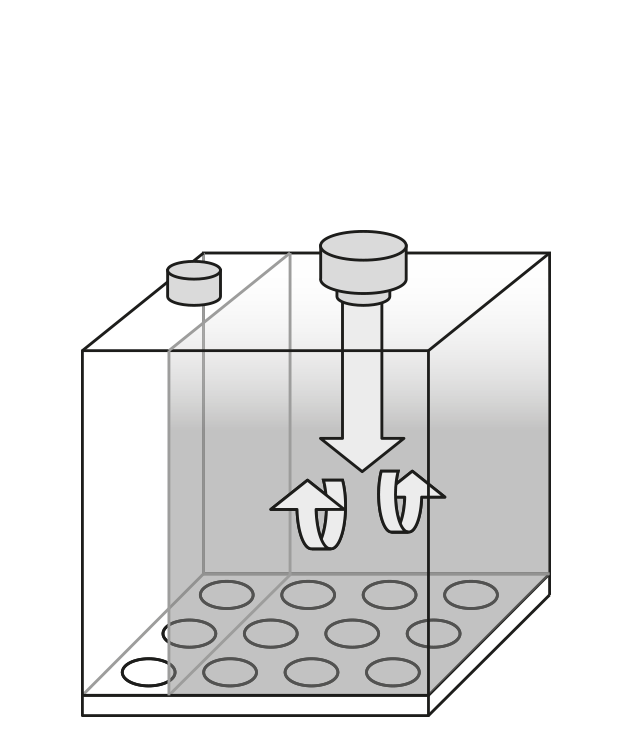

The Cloud system is suitable for nebulization of solutions and suspensions. Fields of application are virus research, screening of inhaled drugs and toxicity testing of inhaled substances such as chemicals or nanoparticles.

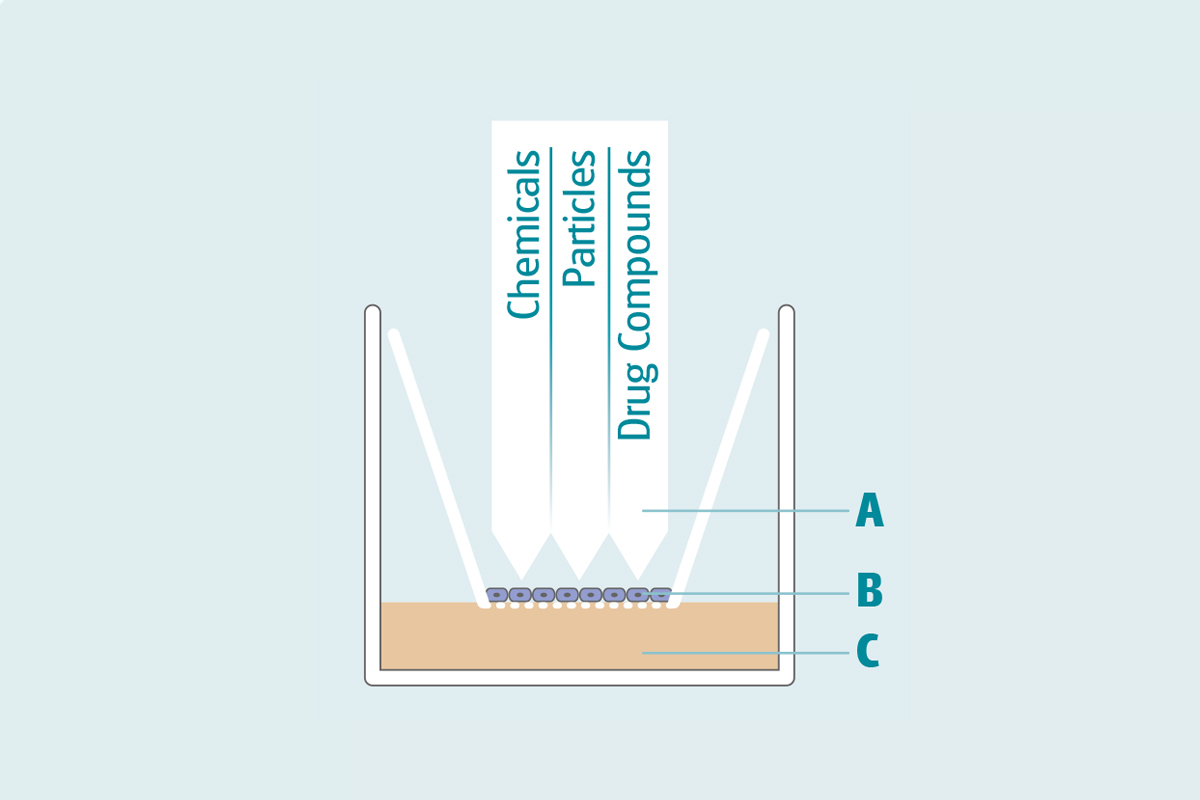

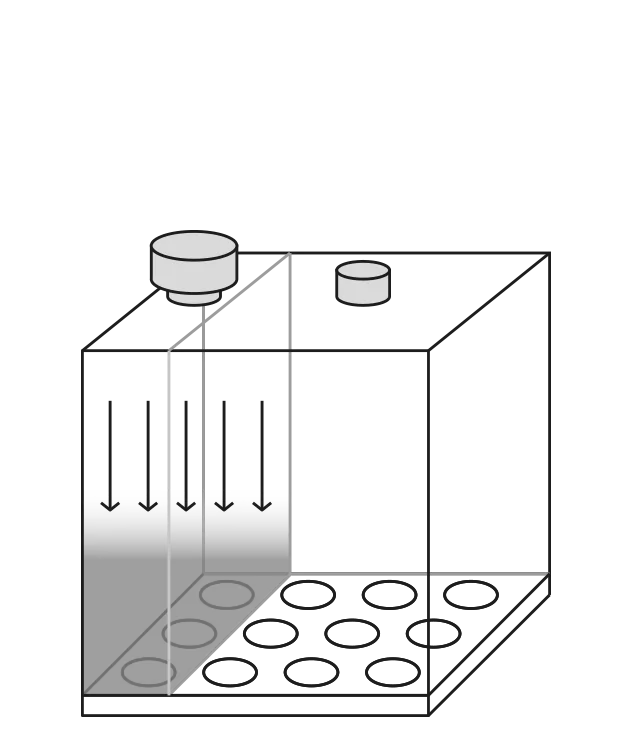

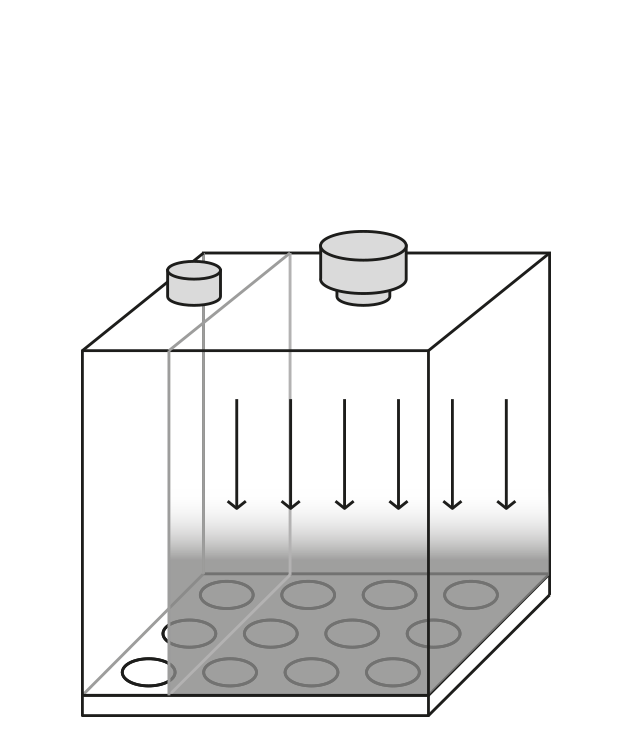

In response to the scientific need to expose in physiologically relevant conditions, the VITROCELL® Cloud Alpha exposure devices have been specifically designed to enable direct exposure of mammalian cells or tissue at the Air/Liquid Interface. Here the cell cultures are not covered with media as opposed to submerged conditions which cause an undesired interaction of the formerly airborne substances with the culture media.

Cell systems cultivated on membrane inserts are exposed at the Air/Liquid Interface (ALI) so that the test substances are received directly. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

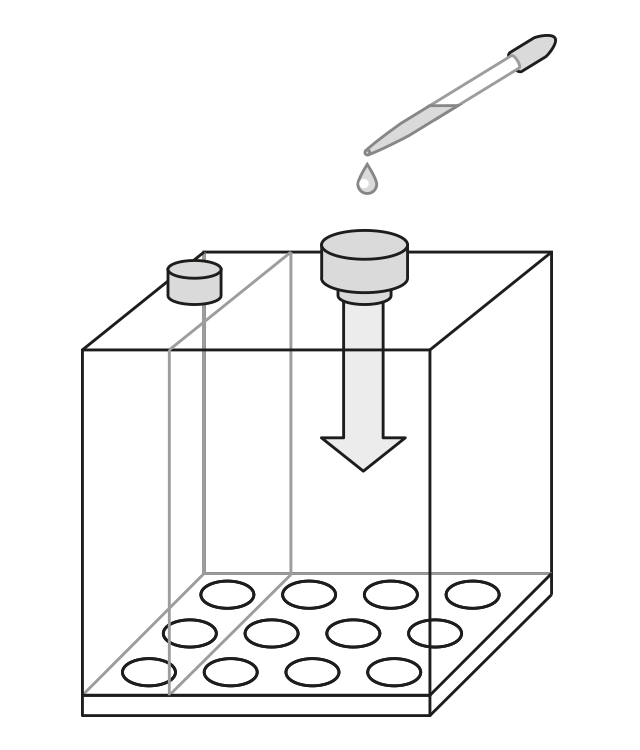

A: Direct and controlled exposure of test atmosphere to cells

B: Cells on membrane

C: Media below cells

The QCM sensor is integrated in the Cloud Alpha 6 exposure module. It is capable of measuring the deposited mass at a resolution of 10 nanogram/cm2 per second. Results are reported online by the VITROCELL Monitor software. Data is presented in graphs and stored in MS Excel®.

The system offers a selection of three types of vibrating mesh nebulizers, allowing users to choose the most suitable option based on the type of substance, with droplet MMADs of 2.5–6.0 µm, 4.0–6.0 µm, 12 µm, 17 µm, and 20 µm.

With a recommended nebulization volume of 200 µL for the Cloud Alpha 12, the device is especially well-suited for experiments where only small amounts of test material are available.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!