for 96-well HTS plates

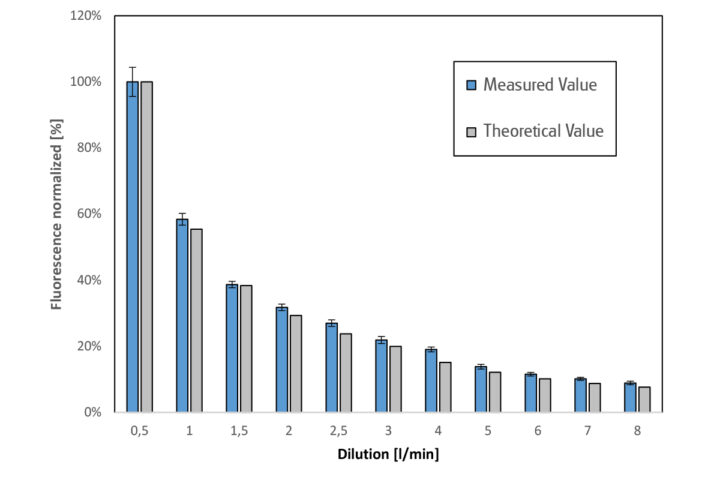

The VITROCELL® 96 Exposure System has been specifically designed and engineered to facilitate the research of human cell cultures in direct exposure to airborne substances such as gases, complex mixtures and particles including nanoparticles. The system authentically simulates the conditions of human physiological exposure. Up to 11 dilutions with 8 replicates are used for for exposure to test substances and the 12th insert row for clean air control with 8 replicates.

Each dilution represents a different dose concentration, so that a complete dose/response profile can be obtained in one experiment.

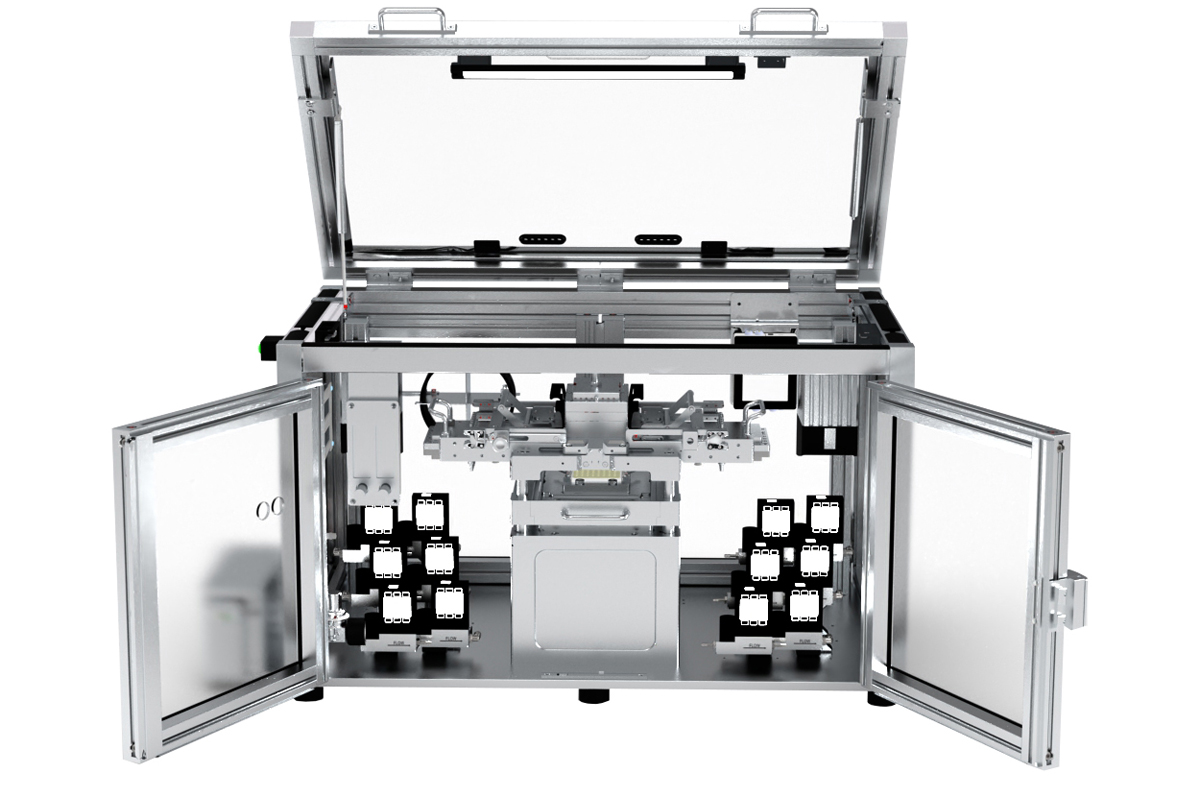

The system is integrated in the Climatic Chamber which enables a stable temperature of 37° C for all components. The benefits are condensation-free operation and a stable humidity level for exposure. The integrated humidification system features a pre-heating of dilution air. All flow controllers are mounted inside the chamber for constant temperature and increased humidity output.

The cell cultures are exposed at the Air/Liquid Interface on 96 membranes of the HTS plate using low flow rates of the aerosol.

After exposure, the cells are further processed to measure a wide range of endpoints e.g. cytotoxicity, genotoxicity, proliferation, cellular and oxidative stress as well as inflammation (see also VITROCELL® assay guide).

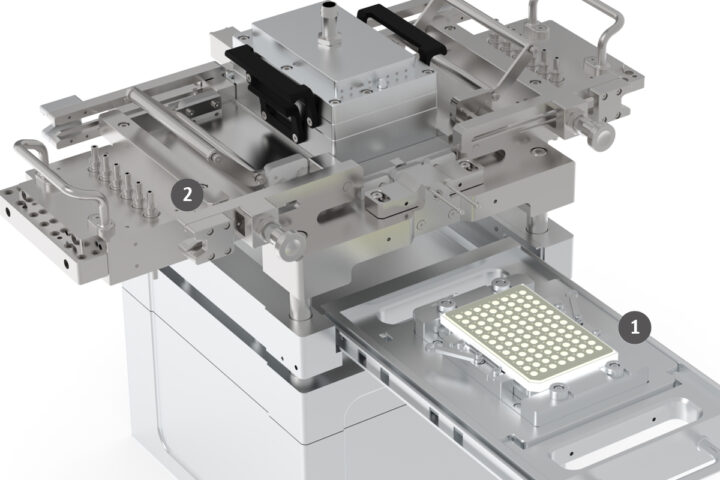

The base module with 96 wells is made of electropolished stainless steel. It may be easily removed from the integrated heating base. Temperature can be programmed individually.

Special sealing and connection mechanisms guarantee a hermetic connection of the base module with the aerosol exposure top. The aerosol exposure top guides the test atmosphere at an individually controlled flow rate to each cell culture membrane.

VITROCELL® exposure systems have been specifically designed and engineered to give researchers the possibility of directly exposing mammalian cells or tissue at the air/liquid interface. Thus, all cell types cultivated on microporous membranes can be used. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

New support and quick-mounting mechanism of dilution systems and exposure top for easier handling.

The docking station guarantees a hermetic connection of the base module with the aerosol exposure top. The flow rate for each of the 96 inlets is controlled by critical orifices which are connected to a vacuum pump.

The integrated 12-fold dilution system can be easily separated from the exposure head for cleaning and maitenance.

The system was evaluated in a comprehensive performance qualification using combustion cigarette aerols. As a conclusion, the system is fit for purpose.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!