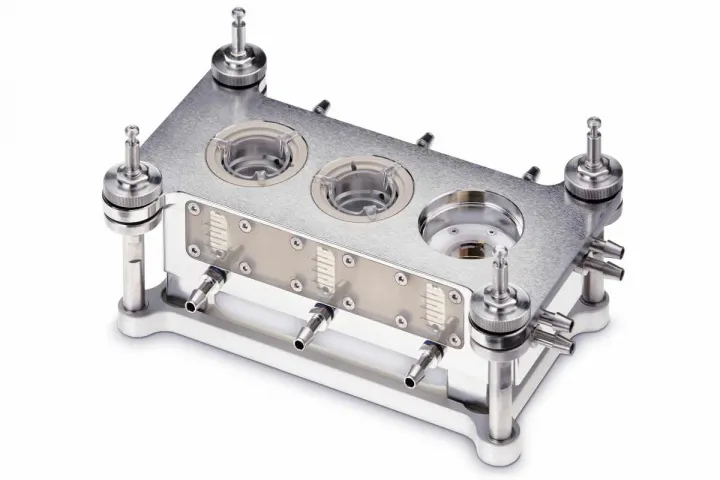

QCM 6 and sQCM 12

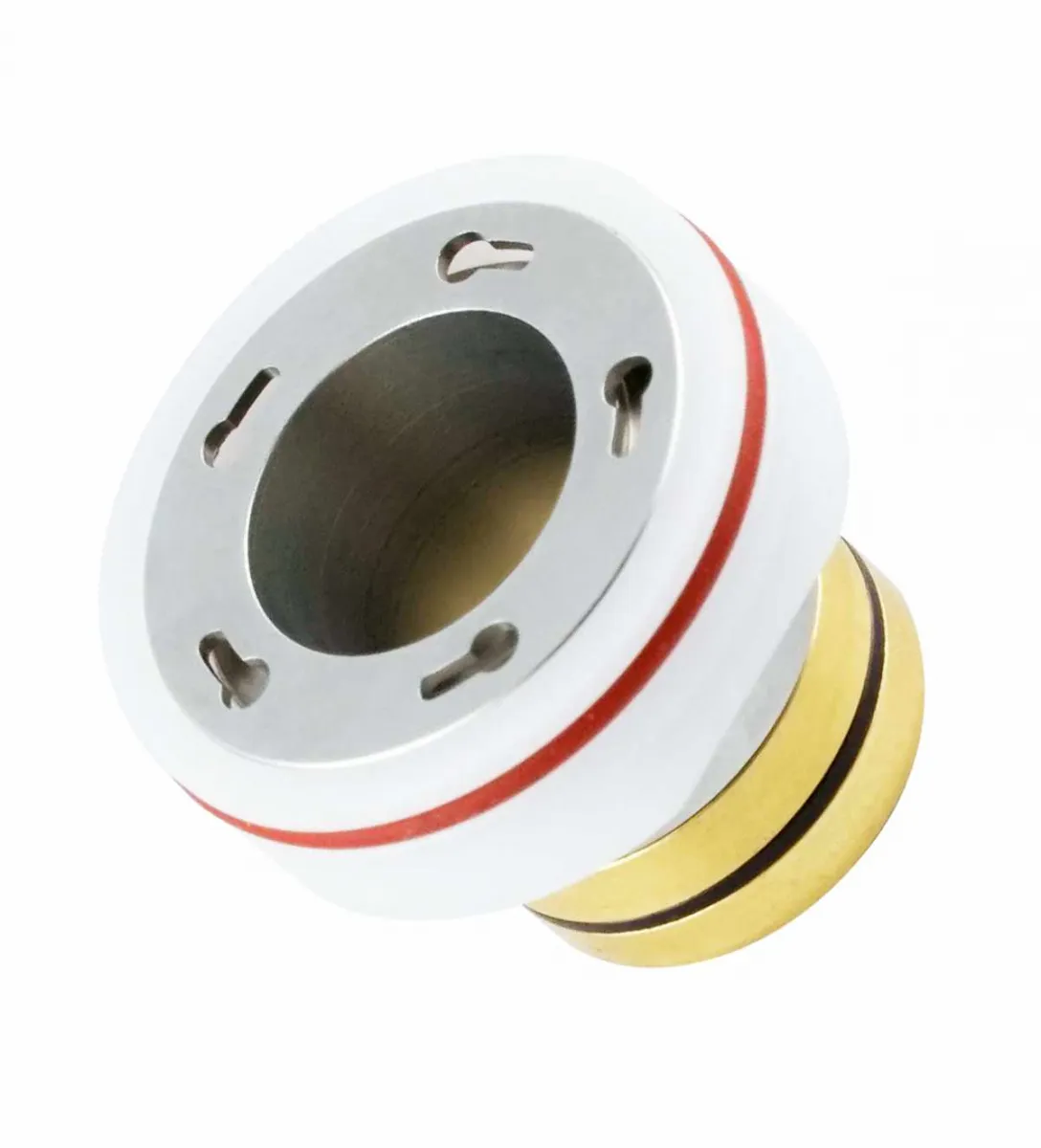

The microbalance sensor can be fitted in all VITROCELL® installations. It is capable of measuring the deposited mass in the module at a resolution of 10 nanogram/cm2 per second.

The sensors can be placed in all medium compartments to validate mass deposition in the module. After validation, they may be removed so that the experiment can be carried out using the cell culture inserts. Alternatively, one microbalance sensor can remain in the module to monitor the dose during exposure. The remaining compartments of the module are used for cell culture inserts.

VITROCELL® Microbalance Sensor - optimal for dose-response measurement.

The VITROCELL® sQCM 12 is the next step in the evolution of dosimetry methods in cell culture exposure systems. It simplifies the usage of conventional Quartz Crystal Microbalances suitable for VITROCELL® 12 modules while maintaining the working principle, precision and accuracy of the balances you’re used to.

We have redesigned the entire sensor from scratch, enabling not only extremely high stability and exact measurements, but also eliminating the need for tools during service and cleaning for maximum user-friendliness.

With the advanced VITROCELL® software, deposition data in ng/cm2 for max. 9 microbalances is attainable online. The data is logged into a .csv file, which can be opened with Excel®.

With the advanced VITROCELL® Dosimetry Software deposition data in ng/cm2 of up to 8 microbalance sensors as well as for 8 photometers is made attainable in a combined view.

The VITROCELL® Monitor software is capable to record 5 different parameters:

The software supports multiscreen use. By undocking charts from the main window they can be placed free in size and position or on a second screen.

VITROCELL® Monitor software GLP Edition was developed for laboratories operating under GLP conditions. This software upgrade assures tracability to high standards.

We are here to help.

Don't hesitate to contact us on your questions regarding our products and services!